Every three years, representatives in the global grain-based food industry gather at the International Baking Industry Exposition (IBIE), also known as the Baking Expo, where participants learn and discover key innovations in the industry. The show runs from Sept. 7 to Sept. 11 in Las Vegas, at the Las Vegas Convention Center.

AZO will debut the AZO COMPONENTER® Step at Booth #5231, and we are happy to answer questions about how the system can improve the automation and material flow of small ingredients.

AZO Inc. General Manager Chuck Kerwin has a specific objective for the 2019 show.

“Our goal is to introduce the COMPONENTER® Step to a target market,” Kerwin said. “It’s the first time we’ve shown it. Heretofore, it was not publicized in the U.S. market.”

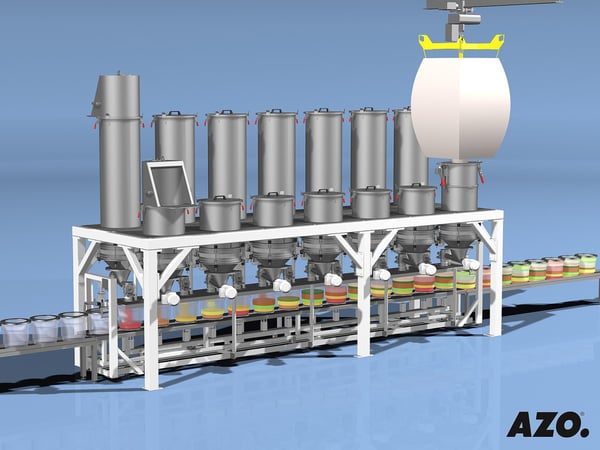

The AZO COMPONENTER® Step, for automatic weighing of minor and micro components

The AZO COMPONENTER® Step, for automatic weighing of minor and micro components

The main advantage of the COMPONENTER® Step is functionality.

“It’s a pretty slick little system,” Kerwin said. “It is relatively low priced in comparison to the other componenter products. Within the baking industry, it fills a very specific need for being able to automate small ingredient dosing.”

Jason Holst, technical sales manager at AZO Inc., said that for those who currently have a process in place for weighing multiple ingredients into a mixture or extruder, a COMPONENTER® Step will take make that process more automatic.

“You put in a combination of recipe and weighments – it automatically weighs it at each stop along where the feeder is located,” Holst said. “That’s going to eliminate human error. It’s going to be all automatic. Accuracy is going to go up.”

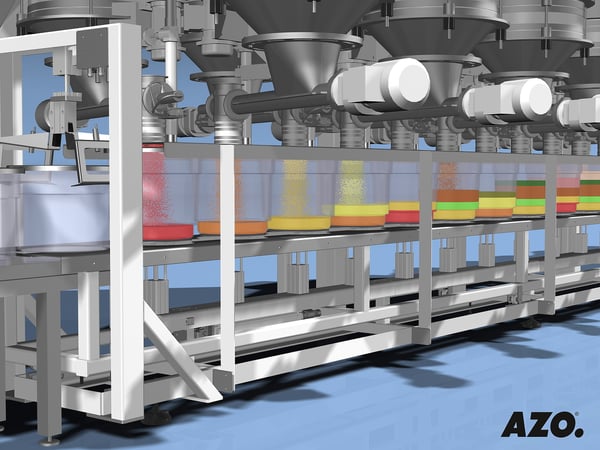

Metering and weighing of components into target containers

Metering and weighing of components into target containers

Holst said that the COMPONENTER® Step is expandable and also increases the ability to track and trace materials.

As new artisanal breads appear on shelves and the movement toward specialty bread increases in America, IBIE 2019 claims to offer the largest event in the Western Hemisphere for the industry.

“The American palate has gotten far more sophisticated when it comes to bread,” Kerwin said. “It's a very dynamic industry in the U.S. There are a lot of people introducing new products in the U.S. – new baked goods. You name it, there are a million varieties.”

From brioches and croissants to donut variations and even products made with cannabidiol (CBD), Kerwin said automation is a great way for operations to scale up, increase production, reduce manpower and reduce costs. Transitioning from using bags to super sacks with a Big Bag Unloader could be the first step toward these changes.

“It could be a huge game-changer for the right bakery at that critical point,” Kerwin said. “There is a lot of cool innovation in the United States food industry being generated by a lot of people. Every once in a while somebody hits a home run, their business takes off and they need to scale up production really fast.”

If you’d like to talk about any problems in ingredient automation that require solutions, such as bulk material handling or bulk bag unloader systems, be sure to browse the AZO blog. Check out our Configurator for bulk handling and discharge requirements, or contact our sales team if you have any questions.