AZO’s heavy-duty super sack unloader — or bulk bag unloader, as it’s also called — is designed to unload and discharge any and all materials from bulk bags.

Bulk Ingredient Handling in the Snack Industry

Crunchy or soft, crisp or sticky, savory or sweet — producing the sheer variety of snack options consumers crave can be complex without an optimal engineered bulk ingredient handling system.

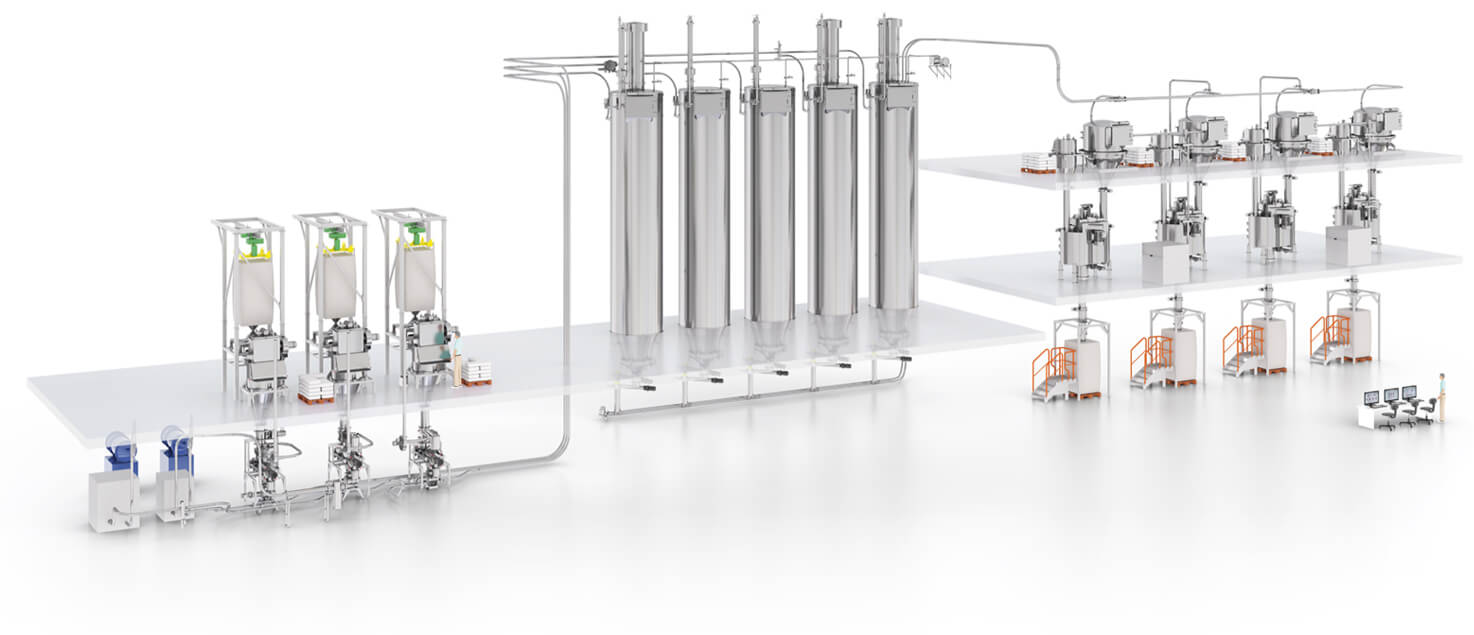

Bulk Ingredient Handling for the Snack Industry: Overview

The vast range of bulk ingredients used to manufacture snacks — including flour, sugar, bits, morsels, & inclusions, and cheese powder — is just one of many challenges faced in the snack industry. Beyond managing the variety of unique snack ingredient characteristics, bulk handling systems must also provide dependable first-in/first-out flow to maximize product freshness, maintain batch control, preserve product purity, and mitigate dust. Whether a recipe calls for flowable powders, grains, granules, or add-ins, AZO’s design and engineering team will deliver the optimal bulk ingredient handling solution with safety, accuracy, and reliability baked in.

Typical Snack Industry System

Pressure Blower (Buyout by AZO)

Centrifugal Screener E-Series

AZO screeners ensure foreign materials never have the chance to enter your production process.

Ingredient Feeding Station

Ingredient Storage Silo

Robust and space-efficient, AZO’s silos provide vertical storage solutions for dry and free-flowing bulk ingredients.

Product Convey Line

Engineered for precision and efficiency, pneumatic conveying of bulk ingredients utilizes the force of air or specialty gas to move bulk materials through intricate pipelines from delivery to storage to production.

Minor Ingredient Feeding Station

DFS Dosing Feed Screw

The AZO DFS dosing screw allows for the continuous and discontinuous conveying and metering of bulk materials in conveying lines, scales, and more.

Bulk Bag Filling Station

Based on intelligent, modular components, our big bag filling systems are available in a variety of configurations to meet individual requirements.

Dry Ingredient Mixer (Buyout by AZO)

AZO® MIXOMAT combines four key processing stages — transporting, dosing, weighing, and mixing — in one compact, economical system. Bringing these stages together in a single system achieves an exemplary degree of efficiency in production.

Bulk Scale Receiver

AZO’s precision batching systems are tailored specifically to meet different material, accuracy, and operational needs.

Controls Automation

Efficiently streamline bulk ingredient handling with advanced control automation.

Bulk Ingredient Handling for the Snack Industry: Common Challenges

Snack manufacturers must meet hygiene and consumer safety requirements.

Snack manufacturers must meet hygiene and consumer safety requirements.

Food safety is a critical concern for snack manufacturers, as contamination can not only affect end product quality, but also pose risks to consumers. Whether dosing or weighing, snack manufacturers must comply with proper hygienic handling practices for all bulk ingredients through regular sanitation and wash-downs. They must also eliminate cross-contamination risks, verify cleanliness, and prevent ingredient cross-contact.

Variety of bulk snack ingredient characteristics.

Variety of bulk snack ingredient characteristics.

New ingredients and changing snack recipes.

New ingredients and changing snack recipes.

To keep pace with constantly evolving trends and consumer preferences, snack recipes can often change, with new ingredients introduced and other ingredients eliminated. These new bulk snack ingredients can present new handling challenges in an existing system, requiring process or equipment adjustments.

Snack manufacturers must contain dust.

Snack manufacturers must contain dust.

A method for containing the high volumes of dust generated by many ingredients used in snack manufacturing should be included in every bulk material handling system design. Fugitive dust can lead to any number of problems, including attracting vermin, operator exposure, or in the worst case, combustion. Improper dust control creates an unsafe working environment for personnel and increases the risk of possible product contamination.

Proper storage and isolation of bulk ingredients.

Proper storage and isolation of bulk ingredients.

Individually storing and isolating bulk ingredients from one another is a critical challenge. Many snack manufacturing facilities must handle different ingredients with different characteristics and in significantly different amounts. The unique qualities of each ingredient and the amount required in each recipe must be considered when selecting bulk storage and handling equipment.

Operator safety and ergonomics.

Operator safety and ergonomics.

The safety and well-being of personnel is a concern that spans all industries, including snack manufacturing. To help keep employees safe and reduce the risk of ergonomic injuries and accidents, it is important to utilize semi- or fully-automated bulk ingredient handling systems that are easy to operate, troubleshoot, and maintain.

Bulk Ingredients for the Snack Industry

-

Sugar

Sugar

Sugar

Sugar is an extremely common ingredient and often included in many bulk ingredient handling operations, such as snacks, mixes and blends, and candy confectionary. Whether it’s handled in a granular, crystalline form or as a powder, sugar is hygroscopic (which leads to clumping) and generates highly combustible dust. Careful consideration of these characteristics by AZO’s design and engineering team ensures the design of a bulk sugar handling system that delivers safe, reliable flow.

-

Bits, Morsels, Inclusions

Bits, Morsels, Inclusions

Bits, Morsels, Inclusions

Bits, morsels, and inclusions are the large, identifiable ingredients often used in manufacturing food such as snacks, candy confectionary, and mixes and blends. Inclusions are often explicitly advertised on product packaging, so their presence is both expected and verified by consumers. Frequently sticky, prone to clumping, or easily crumbled or broken (friable), bulk ingredient handling of bits, morsels, and inclusions requires a high degree of expertise. Careful consideration of each ingredient’s unique characteristics ensures the bulk handling system delivers consistent, reliable flow that addresses the challenges of bits, morsels, and inclusions.

-

Milk/Cheese Powder

Milk/Cheese Powder

Milk/Cheese Powder

Depending on their source — either animal or vegetable — milk and cheese powders have either high fat or high protein content. Either way, milk and cheese powders complicate bulk material handling. Whether they’re used in producing snacks, mixes and blends, or candy and confections, ensuring their smooth flow through a process is key to effective bulk handling. Maintaining proper environmental conditions prevents the separation or loss of fats, while proper dust mitigation minimizes explosion risks. Beyond managing unique ingredient characteristics, dry bulk handling systems must also provide dependable first-in/first-out flow to maximize product freshness, maintain batch control, and preserve hygienic conditions. AZO’s design and engineering team will deliver the dry bulk ingredient handling solution that safeguards product purity for any milk or cheese powder.

-

Mixes & Blends

Mixes & Blends

Mixes & Blends

Using mixes and blends as ingredients to produce snacks, candy confectionery, or baking mixes and blends, requires several considerations to ensure the mix remains blended through production and packaging processes. The key to their effective bulk handling is in the engineering and design of an automated bulk process solution. The system must accommodate the unique characteristics of each mix or blend to prevent it from separating into its component parts. Dry bulk handling systems must also maintain batch control, preserve hygienic conditions, and mitigate dust. Regardless of the recipe, AZO’s design and engineering team will deliver the dry bulk ingredient handling solution that safeguards product purity and consistency.

Sugar

Sugar is an extremely common ingredient and often included in many bulk ingredient handling operations, such as snacks, mixes and blends, and candy confectionary. Whether it’s handled in a granular, crystalline form or as a powder, sugar is hygroscopic (which leads to clumping) and generates highly combustible dust. Careful consideration of these characteristics by AZO’s design and engineering team ensures the design of a bulk sugar handling system that delivers safe, reliable flow.

Bits, Morsels, Inclusions

Bits, morsels, and inclusions are the large, identifiable ingredients often used in manufacturing food such as snacks, candy confectionary, and mixes and blends. Inclusions are often explicitly advertised on product packaging, so their presence is both expected and verified by consumers. Frequently sticky, prone to clumping, or easily crumbled or broken (friable), bulk ingredient handling of bits, morsels, and inclusions requires a high degree of expertise. Careful consideration of each ingredient’s unique characteristics ensures the bulk handling system delivers consistent, reliable flow that addresses the challenges of bits, morsels, and inclusions.

Milk/Cheese Powder

Depending on their source — either animal or vegetable — milk and cheese powders have either high fat or high protein content. Either way, milk and cheese powders complicate bulk material handling. Whether they’re used in producing snacks, mixes and blends, or candy and confections, ensuring their smooth flow through a process is key to effective bulk handling. Maintaining proper environmental conditions prevents the separation or loss of fats, while proper dust mitigation minimizes explosion risks. Beyond managing unique ingredient characteristics, dry bulk handling systems must also provide dependable first-in/first-out flow to maximize product freshness, maintain batch control, and preserve hygienic conditions. AZO’s design and engineering team will deliver the dry bulk ingredient handling solution that safeguards product purity for any milk or cheese powder.

Mixes & Blends

Using mixes and blends as ingredients to produce snacks, candy confectionery, or baking mixes and blends, requires several considerations to ensure the mix remains blended through production and packaging processes. The key to their effective bulk handling is in the engineering and design of an automated bulk process solution. The system must accommodate the unique characteristics of each mix or blend to prevent it from separating into its component parts. Dry bulk handling systems must also maintain batch control, preserve hygienic conditions, and mitigate dust. Regardless of the recipe, AZO’s design and engineering team will deliver the dry bulk ingredient handling solution that safeguards product purity and consistency.

AZO’s Bulk Ingredient Handling Solutions for the Snack Industry: Outcomes & Benefits

AZO’s experienced design engineers understand the unique challenges facing snack manufacturers. Every bulk snack ingredient handling system we create incorporates equipment and solutions that reliably and effectively address the challenges outlined above. As a single-source provider of automated ingredient system equipment, AZO designs and engineers bulk material handling solutions that enhance both safety and productivity in your facility.

With an AZO bulk ingredient handling system, your snack manufacturing operation will:

- Maintain proper hygiene and eliminate cross-contamination risks with easy-to-clean equipment.

- Easily accommodate a broad range of bulk snack ingredient characteristics.

- Receive ongoing support in adapting to changing recipes and new ingredients.

- Keep employees safe by reducing ergonomic injuries and accidents.

- Consistently and accurately comply with government track-and-trace requirements.