Robust and space-efficient, AZO’s silos provide vertical storage solutions for dry and free-flowing bulk ingredients.

Bulk Ingredient Handling in the Chemical Industry

AZO engineers durable, reliable, and accurate bulk ingredient handling systems that protect employees while supporting your chemical manufacturing operation.

Bulk Ingredient Handling for the Chemical Industry: Overview

To ensure accurate, evenly-dispersed chemical blends, AZO’s bulk ingredient handling systems precisely measure and dispense compounds and ingredients — such as resins, TiO2, fumed silica, or diatomaceous earth — into blending machinery at exactly the right time. Further, our equipment ensures the safe handling of toxic and dangerous materials throughout your process. Rely on AZO’s engineering-centric experience in chemical manufacturing to design and support the bulk ingredient handling system your operation needs.

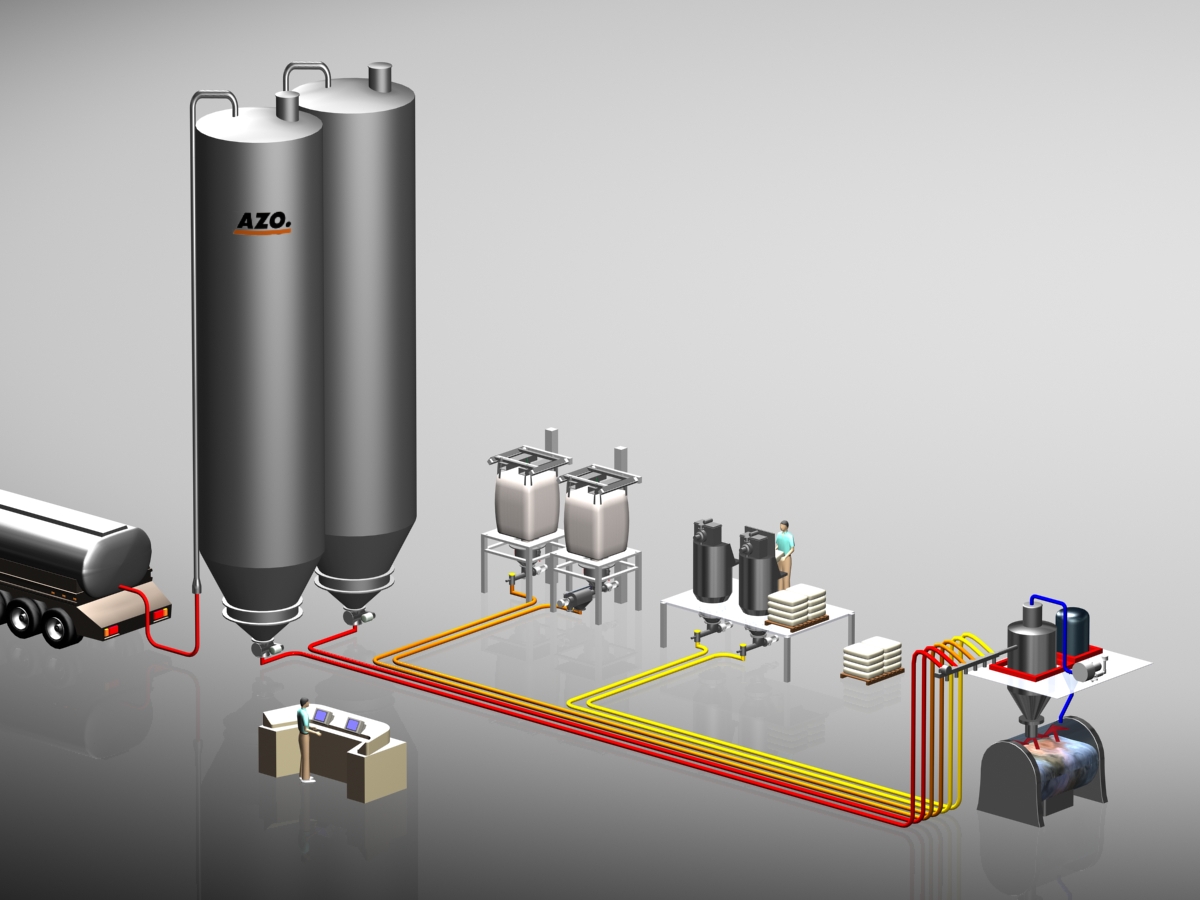

Typical Chemical Industry System

Rotary Valve (Buyout by AZO)

VB Vibration Bottom Discharging Device

AZO’s vibration bottom, or VB for short, allows for the reliable discharge of powdery, crystalline, high-fat, and granular bulk materials from hoppers.

Controls Automation

AZO’s Bulk Ingredient Control Automation plays a vital role in enhancing the efficiency and quality of production processes in various industries.

Bulk Bag Unloading Station

AZO’s heavy-duty super sack unloader — or bulk bag unloader, as it’s also called — is designed to unload and discharge any and all materials from bulk bags.

Centrifugal Screener DA-Series

AZO screeners ensure foreign materials never have the chance to enter your production process.

Ingredient Feeding Station

DFS Dosing Feed Screw

The AZO DFS dosing screw allows for the continuous and discontinuous conveying and metering of bulk materials in conveying lines, scales, and more.

Product Convey Lines

AZO designs and engineers many different types of pneumatic conveying systems for bulk ingredient handling, each uniquely designed for specific projects.

Multiport Valve

Rotary Valve (Buyout by AZO)

Dry Powder Mixer (Equipment by Customer)

Bulk Ingredient Handling for the Chemical Industry: Common Challenges

Chemical manufacturers must properly handle hazardous materials.

Chemical manufacturers must properly handle hazardous materials.

Compounds and chemicals used in manufacturing must be safely stored, dispensed, and conveyed within an operation. Equipment must be capable of completely containing all hazardous materials to safeguard the health and well-being of employees and to minimize insurance risks.

Chemical manufacturers must contain dust.

Chemical manufacturers must contain dust.

A method to contain the high volumes of dust generated by many bulk ingredients used in chemical manufacturing should be included in every bulk material handling system design. Fugitive dust can lead to any number of problems, including operator exposure, or in the worst case, combustion. Improper dust control creates an unsafe working environment for personnel and possible product contamination.

Proper storage and isolation of bulk ingredients.

Proper storage and isolation of bulk ingredients.

Individually storing and isolating bulk ingredients from one another is a critical challenge. Many manufacturing facilities must handle different chemicals with different characteristics and in significantly different volumes. The unique qualities of each chemical and the amount required in each product must be considered when selecting bulk storage and handling equipment.

Bulk Ingredients for the Chemical Industry

-

TiO2

TiO2

TiO2

Bright white and used in a variety of everyday products, TiO2 is an extremely common ingredient in many bulk ingredient handling operations, including personal products, poly and plastics, chemicals, and pharmaceuticals. Characterized by fine particles that flow poorly, TiO2 is moderately abrasive and forms heavy, dense clumps. These critical attributes can make emptying this ingredient out of storage vessels or successfully conveying it challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a TiO2 handling system is safe, reliable, and dust free.

-

Resin

Resin

Resin

Incorporated into a variety of products in unique and exacting formulations, resin is a diverse ingredient category that includes applications in PVC dry blends, plastics, and chemicals. Further, it is often toxic and generates highly combustible dust. These critical attributes can make successfully conveying it safely and without clogs challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a bulk resin handling system is safe, reliable, and dust free.

-

Fumed Silica

Fumed Silica

Fumed Silica

Composed of very fine, non-porous particles of silicon dioxide (SiO2), fumed silica powder has a high surface area and light density. Due to its extremely high surface area, it is an effective thickening and reinforcing agent in many products. Whether it’s used in personal products, poly and plastics processing, or chemicals, fumed silica’s unique characteristics require special material handling solutions. It is prone to producing high amounts of dust, which is easily combustible and a personnel risk. AZO’s engineering team carefully considers each of these factors to design a bulk fumed silica material handling system that ensures safe, reliable flow.

-

Diatomaceous Earth

Diatomaceous Earth

Diatomaceous Earth

A type of crystalline silica made from pulverized sedimentary rock, diatomaceous earth comes in many forms, including pellets, particles, or powder. In its powdered form, this naturally occurring ingredient has a high surface area and light density. It is an ingredient used in a range of beverage and food grade filtration applications and in many industrial applications. Whether it’s used in manufacturing of personal products, pharmaceuticals, chemicals, or beverage filtration, diatomaceous earth powder’s unique characteristics require special material handling solutions. It is prone to producing high amounts of dust, which is a carcinogen. AZO’s engineering team carefully considers each of these factors to ensure the design of a diatomaceous earth handling system is safe, reliable, and dust free.

TiO2

Bright white and used in a variety of everyday products, TiO2 is an extremely common ingredient in many bulk ingredient handling operations, including personal products, poly and plastics, chemicals, and pharmaceuticals. Characterized by fine particles that flow poorly, TiO2 is moderately abrasive and forms heavy, dense clumps. These critical attributes can make emptying this ingredient out of storage vessels or successfully conveying it challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a TiO2 handling system is safe, reliable, and dust free.

Resin

Incorporated into a variety of products in unique and exacting formulations, resin is a diverse ingredient category that includes applications in PVC dry blends, plastics, and chemicals. Further, it is often toxic and generates highly combustible dust. These critical attributes can make successfully conveying it safely and without clogs challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a bulk resin handling system is safe, reliable, and dust free.

Fumed Silica

Composed of very fine, non-porous particles of silicon dioxide (SiO2), fumed silica powder has a high surface area and light density. Due to its extremely high surface area, it is an effective thickening and reinforcing agent in many products. Whether it’s used in personal products, poly and plastics processing, or chemicals, fumed silica’s unique characteristics require special material handling solutions. It is prone to producing high amounts of dust, which is easily combustible and a personnel risk. AZO’s engineering team carefully considers each of these factors to design a bulk fumed silica material handling system that ensures safe, reliable flow.

Diatomaceous Earth

A type of crystalline silica made from pulverized sedimentary rock, diatomaceous earth comes in many forms, including pellets, particles, or powder. In its powdered form, this naturally occurring ingredient has a high surface area and light density. It is an ingredient used in a range of beverage and food grade filtration applications and in many industrial applications. Whether it’s used in manufacturing of personal products, pharmaceuticals, chemicals, or beverage filtration, diatomaceous earth powder’s unique characteristics require special material handling solutions. It is prone to producing high amounts of dust, which is a carcinogen. AZO’s engineering team carefully considers each of these factors to ensure the design of a diatomaceous earth handling system is safe, reliable, and dust free.

AZO’s Bulk Ingredient Handling Solutions for the Chemical Industry: Outcomes & Benefits

With an AZO bulk ingredient handling system, your chemical manufacturing operation will:

- Ensure product consistency and quality via highly accurate automatic weighing and dosing of bulk, minor, and micro ingredients.

- Easily accommodate a broad range of chemicals and compounds.

- Keep employees safe by reducing ergonomic injuries and accidents.

- Safely contain dust and hazardous chemicals to significantly reduce explosion risk.