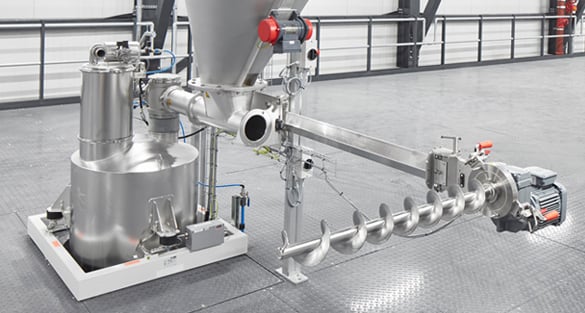

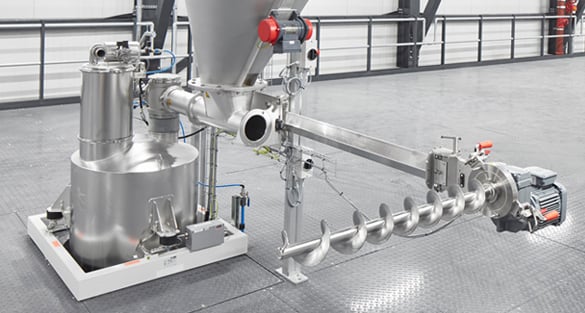

Precise Conveying & Dosing of Bulk Materials

AZO's dosing screws provide both continuous and intermittent conveying and metering of bulk materials through conveying lines, scales, and more. These units are suitable for handling nearly all kinds of bulk ingredients in the food and beverage, plastics, chemical, and pharmaceutical industries.

The Benefits You Can Expect

The AZO dosing screw features a high-quality nickel chromium design and a sturdy construction that can handle vibrations in operations. Other advantages of the system include:

- The convenience of a pneumatically operated shutoff valve

- Fast and easy installation through a slotted-hole flange

- Customizable screw length for unique installations

- High output in coarse-feed operations

- The highest dosing accuracy in fine-feed operations

- A modular design that supports easy integration

- Quick-release clamps that allow for easy inspection and cleaning

How AZO's Dosing Screw Works

The bulk material first enters the screw housing through the product inlet. From there, the material is transferred to the screw outlet. An integrated variable frequency control device allows for precise feeding, metering, and weighing operations. When the set weight is reached, the screw outlet is pneumatically closed. This ensures precision and accuracy during operation while minimizing errors.