Engineered for precision and efficiency, pneumatic conveying of bulk ingredients utilizes the force of air or specialty gas to move bulk materials through intricate pipelines from delivery to storage to production.

Bulk Ingredient Handling in the PVC Dry Blends Industry

Regardless of the specific mix required to produce your PVC dry blend, AZO can create the durable, reliable bulk ingredient handling system that accurately produces the precise formula needed.

Bulk Ingredient Handling for the PVC Dry Blends Industry: Overview

Integrating polyvinyl chloride (PVC) with various ingredients to manufacture PVC dry blends demands a high level of process accuracy. Regardless of the exacting standards required for your blend formula, AZO’s bulk ingredient handling systems precisely measure and dispense resins, modifiers, stabilizers, additives, fillers, and minor ingredients into extruders in the right amounts. Whether your PVC dry blends are being made into pipe, window profiles, or other products, you can rely on AZO. Our engineering-centric experience in PVC dry blend processing ensures innovative, reliable automated systems that deliver high-quality blends every time.

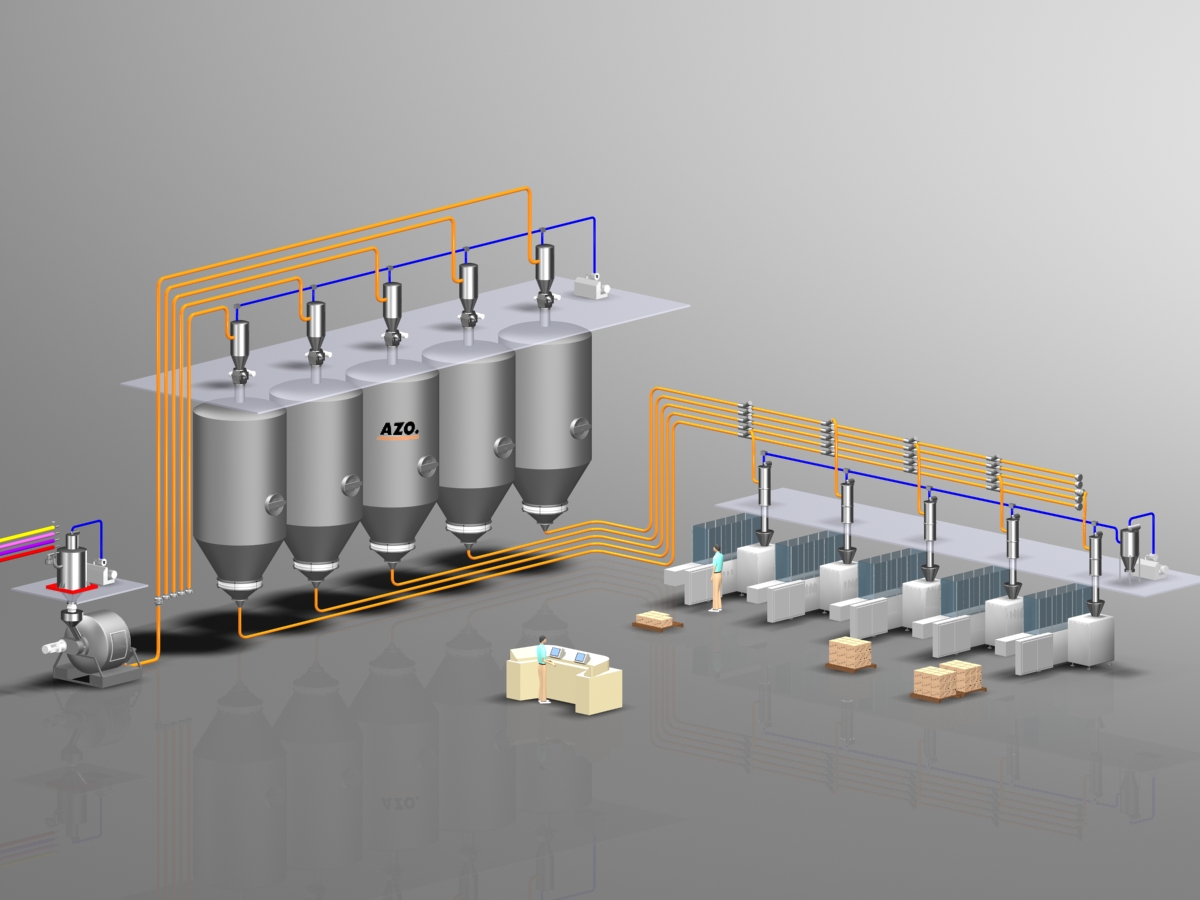

Typical PVC Dry Blends Industry System

Heater / Cooler Mixer (Buyout Equipment)

Vacuum Passthrough Receiver

Rotary Valve (Buyout by AZO)

Product Intermediate Storage Vessels

AZO offers a comprehensive range of bulk ingredient storage systems tailored to meet the distinct needs of different materials and manufacturing processes.

Vacuum Pump (Buyout by AZO)

Control System

Efficiently streamline bulk ingredient handling with advanced control automation.

Vacuum Receiver

Secondary Air Filter

Product Packaging Machine (Provided by Customer)

Bulk Ingredient Handling for the PVC Dry Blends Industry: Common Challenges

Proper and timely introduction of ingredients into the extruder.

Proper and timely introduction of ingredients into the extruder.

Before extruder systems can process materials into a PVC dry blend, weighing and dosing equipment must accurately measure and precisely dispense the appropriate quantities of ingredients. These include modifiers, stabilizers, additives, and fillers. PVC dry blend manufacturers must utilize reliable and accurate equipment to ensure the final product consistently matches required specifications.

Precisely controlled dispensing of additives to extruders.

Precisely controlled dispensing of additives to extruders.

Consistent PVC dry blends require a wide range of specialty ingredients in the manufacturing process. Often dispensed in small amounts, the timing and accuracy of these additives is critical to produce a high-quality PVC blend.

PVC dry blend manufacturers must properly handle hazardous materials.

PVC dry blend manufacturers must properly handle hazardous materials.

Liquid plasticizers and other chemicals used in the production of PVC dry blends must be safely stored, dispensed, and conveyed within an operation. Equipment must be capable of completely containing all hazardous materials to safeguard the health and well-being of employees and to minimize insurance risks.

PVC dry blend manufacturers must contain dust.

PVC dry blend manufacturers must contain dust.

A method for containing the high volumes of dust generated by many ingredients used in PVC dry blend manufacturing should be included in every bulk material handling system design. Fugitive dust or additive leaks can lead to any number of problems, including operator exposure or in the worst case, ignition. Improper dust control creates an unsafe working environment for personnel and increases the risk of combustion.

Bulk ingredient handling requires space for explosion protection.

Bulk ingredient handling requires space for explosion protection.

Bulk ingredient handling systems must include appropriate explosion protection and dust mitigation equipment. This is especially important when upgrading legacy systems, which may require some design creativity to ensure that necessary protection can fit into the available space.

Operator safety and ergonomics.

Operator safety and ergonomics.

The safety and well-being of personnel is a concern that spans all industries, including PVC dry blend manufacturing. To help keep employees safe and reduce the risk of ergonomic injuries and accidents, it is important to utilize semi- or fully-automated bulk ingredient handling systems that are easy to operate, troubleshoot, and maintain.

Bulk Ingredients for the PVC Dry Blends Industry

-

Resin

Resin

Resin

Incorporated into a variety of products in unique and exacting formulations, resin is a diverse ingredient category that includes applications in PVC dry blends, plastics, and chemicals. Further, it is often toxic and generates highly combustible dust. These critical attributes can make successfully conveying it safely and without clogs challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a bulk resin handling system is safe, reliable, and dust free.

Resin

Incorporated into a variety of products in unique and exacting formulations, resin is a diverse ingredient category that includes applications in PVC dry blends, plastics, and chemicals. Further, it is often toxic and generates highly combustible dust. These critical attributes can make successfully conveying it safely and without clogs challenging. AZO’s engineering team carefully considers each of these factors to ensure the design of a bulk resin handling system is safe, reliable, and dust free.

AZO’s Bulk Ingredient Handling Solutions for the PVC Dry Blends Industry: Outcomes & Benefits

With an AZO bulk ingredient handling system, your PVC dry blends manufacturing operation will:

- Ensure product consistency and quality via highly accurate automatic weighing and dosing of dry ingredients and additives.

- Keep employees safe by reducing ergonomic injuries and accidents.

- Safely contain dust and hazardous chemicals to significantly reduce explosion risk.

- Accommodate either vertical or horizontal processing layouts.

AZO’s Bulk Ingredient Handling Systems for the PVC Dry Blends Industry: Equipment & Engineering Solutions

AZO backs the PVC dry blend industry with comprehensive, engineering-centric design and support. Your solution will match your unique requirements and be optimized for the safest, most reliable handling process. AZO automated systems for PVC dry blend plants typically include: