Preserve the Quality of Bulk Solids & Liquids with AZO Screeners

Top-notch production means making sure that contaminants don’t interfere with high-quality raw materials. AZO screeners ensure foreign materials never have the chance to enter your production process. It’s a safeguard your bulk solids and liquids need to support quality assurance.

The Benefits You Can Expect

Keeping bulk solids and liquids free of contaminants is critical to meeting stringent product quality standards in the food, pharmaceutical, chemical, and plastic industries. As a key element of AZO's conveying systems, these screeners support robust quality assurance and deliver the following benefits:

- Peace of mind with comprehensive safety checks

- Ensured adherence to HACCP specifications

- Greater confidence about final product quality

- Prevention of losses and costly equipment downtime

- Superior technology that delivers outstanding service

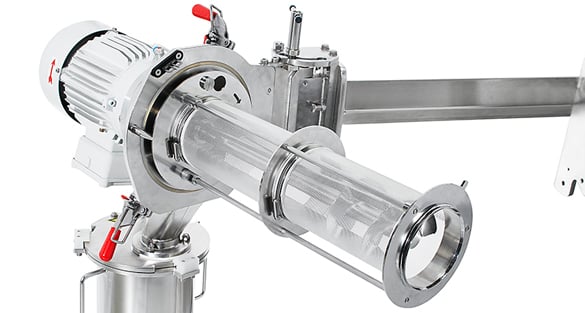

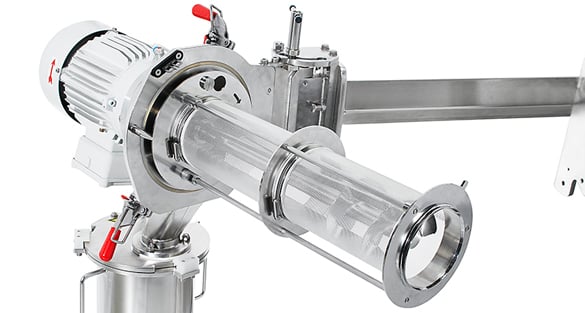

How AZO Screeners Work

AZO screeners are designed to check individual ingredients for contaminants before, during, and after processing. When a material enters a screener, lumps, foreign objects, and other contaminants are automatically removed and discharged into an outlet. With a baffle that prevents the fine proportion of material from entering the outlet, the in-spec screen material continues on in the production process with improved safety and quality.

Browse AZO's Different Screeners

AZO Cyclone Screener Model DA

“Low-profile” screener (perfect for buildings with height restrictions).

AZO Cyclone Screener Type FLF 650

The FLF screener is ideal for screening solids from liquids.

AZO Pneumatic Screener TW650

Screening in pneumatic conveying systems and predominantly used in pressure applications for filling a silo.

Have Questions About AZO Screening Systems? We Can Help.