In manufacturing environments, downtime affects more than just daily output. It disrupts scheduling, increases operating costs, and introduces risk into processes that are designed for consistency. Equipment failures — especially in critical systems like batching, mixing, or conveying — create bottlenecks throughout an entire facility.

To address these issues, manufacturers are turning to predictive maintenance, enabled by modern control systems and industrial sensor networks. It's a proactive approach that helps you forecast equipment issues, optimize maintenance planning, reduce downtime and lower maintenance costs. For AZO’s clients in the food, chemical, and pharmaceutical sectors, these technologies support the kind of uptime and product quality that tight compliance standards command from industrial operations.

Understanding the Maintenance Spectrum

Most plants use one of three maintenance strategies, depending on their budget, staffing, and process maturity:

Reactive Maintenance

Reactive maintenance means equipment is repaired only after it fails. By ignoring equipment health, it avoids upfront costs for sensors, software, or dedicated maintenance staff, which some operations find appealing, particularly when budgets are tight.

However, the tradeoffs are significant. When a machine goes down without warning, it halts production, interrupts delivery schedules, and can threaten customer relationships. Even short periods of downtime can reduce a plant’s overall output and profitability. From AZO’s experience, companies that rely solely on after-the-fact maintenance often face the highest frustration levels when breakdowns occur.

Preventive Maintenance

Preventive maintenance takes a systematic, time-based approach. If a screen typically wears out after 30 days, it might be replaced after 28 — whether or not it shows signs of wear. This scheduled maintenance method improves reliability and is generally easier to manage, especially when using fixed schedules or simple counters in control systems.

The downside is efficiency. Parts may be replaced too early, and maintenance staff may spend time on tasks that aren’t actually necessary. There's also the cost of stocking replacement components for a fixed schedule, which may not reflect real usage.

In one plant that has operated for over 20 years, preventive methods helped reduce reactive maintenance events to just two. That level of reliability naturally improves throughput and minimizes unplanned outages. And if they employed predictive maintenance, as we’ll explore below, reactive maintenance could have been reduced to zero.

Predictive Maintenance

Predictive maintenance uses real-time condition monitoring and trend analysis to determine when equipment is likely to need service. This approach focuses on data collection for the actual performance of each component rather than averages or schedules. A predictive maintenance strategy typically uses sensors, control systems, and software to analyze data and predict potential failures.

For example, AZO can integrate sensors that measure vibration, temperature, electrical current, and acoustics. Over time, these readings establish a performance baseline. When a component begins to deviate from that baseline — such as a motor drawing more current than usual or a screen vibrating at a different frequency — the system flags it. Maintenance can be scheduled before failure, without replacing components prematurely.

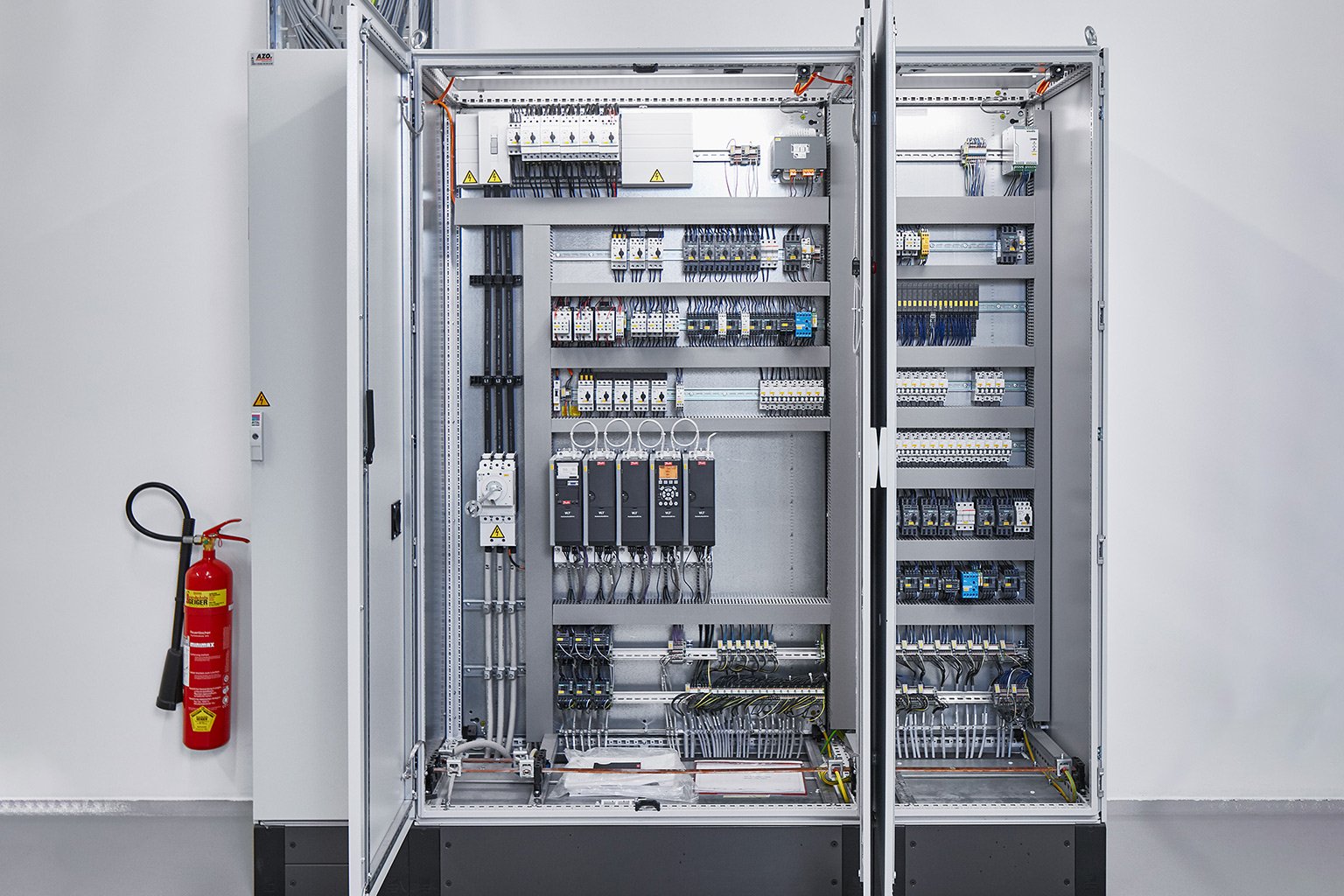

Control Systems and Industrial IoT

Predictive maintenance relies on integrated automation systems to gather and analyze performance data. These systems include:

- PLCs (programmable logic controllers) and SCADA (supervisory control and data acquisition) platforms to manage equipment control and provide operator visibility

- IoT (Internet of Things) sensors to measure temperature, vibration, pressure, current, and more, so that crews can forecast equipment failures

- Cloud or other computing systems to log data and identify patterns

- Machine learning or predictive maintenance software to forecast failures based on trend deviations

AZO works with customers to install sensors on high-risk components, such as motors and mixers, and to design alarms and thresholds that align with operating goals. These systems feed data directly into the control architecture, so alerts can be issued as soon as equipment starts to drift from expected behavior. Maintenance teams have real-time data which helps them spot potential failures and schedule maintenance activities accordingly.

This allows plants to avoid unnecessary shutdowns while still catching issues early. It also improves planning: technicians can schedule repairs during off-shifts or coordinated downtimes, rather than reacting under pressure when production is already impacted.

Real-World Applications of Predictive Systems in Use

In a food production facility, for example, AZO clients use sensors to monitor the protein or moisture content of ingredients like flour as they move through the line. Data is sampled every 30 milliseconds. When a change in composition is detected, recipe adjustments can be made to maintain consistent product quality.

In other cases, vibration sensors installed on legacy mixing equipment provide early warnings about mechanical degradation. These signals are subtle, and might not trigger alarms in a traditional system. But predictive models can detect even slight performance shifts so you can translate them into actionable recommendations.

Data quality is critical in predictive maintenance, because poor quality can lead to inaccurate predictions and ineffective maintenance strategies. Predictive analytics' historical data helps identify patterns which can lead to lower maintenance costs.

Where the Technology Stands Today

While sensors and connectivity are available, the software needed to analyze large volumes of industrial data is still evolving. Many systems today provide simple averages — every 30 seconds or 90 seconds — which still requires human interpretation.

To close that gap, AZO partners with integration teams to help clients make sense of the data. The goal is to connect lab measurements, process variables, and final product outcomes into a cohesive feedback loop. For example, if low protein content increases mixer run time, that information can be used to adjust bake time or motor energy settings further down the line.

Advanced analytics like these give you the edge on complex maintenance procedures. With the right predictive maintenance tools, data analysis empowers your team.

Benefits of Predictive Maintenance Systems

Over time, we expect predictive systems will become increasingly autonomous. Advancements in AI and machine learning will help prioritize maintenance tasks, identify root causes faster, and even trigger parts ordering or rescheduling automatically.

This will require close coordination between plant IT, laboratory services, instrumentation providers, control system engineers, and maintenance teams. AZO plays a central role in bringing those elements together by designing sensor placement strategies, setting data thresholds, and helping integrate analytics into daily operations.

Implementing predictive maintenance is a practical, engineering-based approach to improving plant reliability. It doesn’t rely on guesswork or assumptions; it builds on real data and observable trends. By using control systems and sensors to track equipment performance in real time, manufacturers can maintain throughput, improve product consistency, and plan for service work without affecting production.

As more systems become connected and smarter, the shift from preventive to predictive becomes not just possible, but necessary for long-term efficiency.